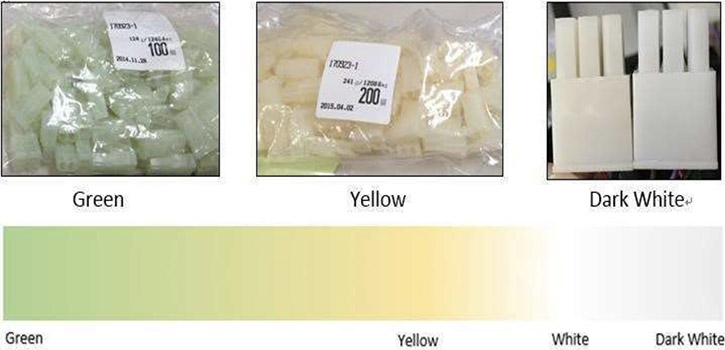

Natural color variation of Nylon

What is natural nylon and why is there such a variance in color?

The chemical process to produce nylon results in a translucent white material in its natural color, before a dye is added for a specific color, such as black.

All the connectors pictured above are natural, so why all the different hues?

Nylon is hygroscopic, meaning it is able to absorb water, and it is the increased moisture content that changes the color from white, to yellow or green, see Fig. 1. This phenomenon doesn't negatively affect the form, fit, or function of the part [1]. In fact, many parts are conditioned after being molded to increase their moisture content, as this improves its strength and flexibility.

Conversely, this moisture content can also pose problems when molding nylon. If you have a 3D printer, you may have encountered print issues due to a higher moisture content, which can be cured by first drying the nylon spool in a low temp oven. A similar process is used to dry nylon pellets for injection molding.

Sources:

[1] TE Connectivity. (October 31, 2020). White Paper: Nylon Discoloration. https://www.te.com/commerce/DocumentDelivery/DDEController?Action=showdoc&DocId=Data+Sheet%7FWP-160037%7FA%7Fpdf%7FEnglish%7FENG_DS_WP-160037_A.pdf%7F172128-1

Created: April 11, 2024